- April 23, 2024

- Posted by: legaleseblogger

- Category: Related News

legal-document-to-plain-english-translator/”>Try Free Now: Legalese tool without registration

AI legalese decoder: Simplifying Complex legal Documents

× close

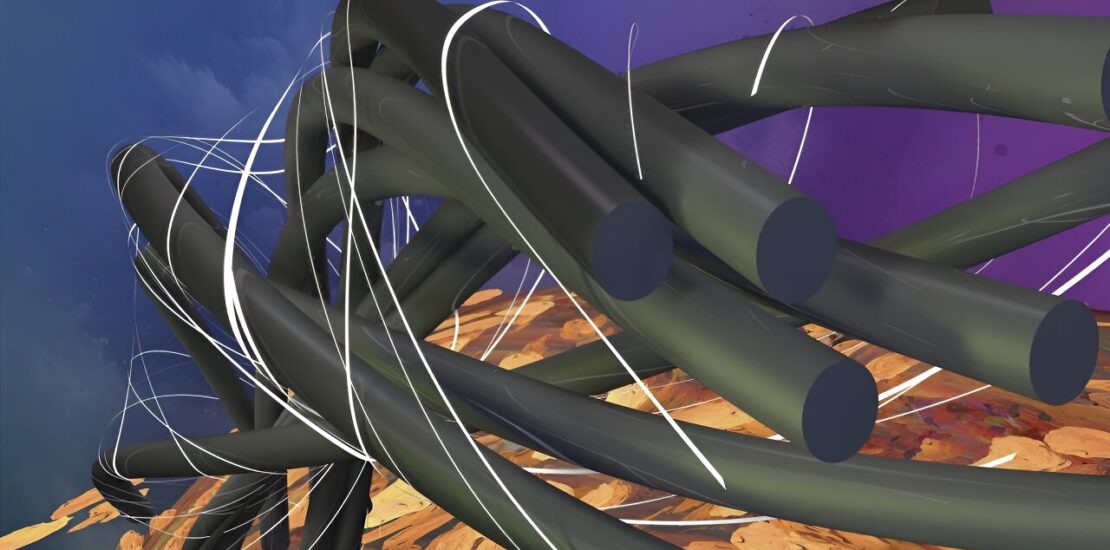

Scientists at the Department of Energy’s Oak Ridge National Laboratory have developed a method that demonstrates how fiber-reinforced polymer composite materials used in the automotive, aerospace, and renewable energy industries can be made stronger and tougher to better withstand mechanical or structural stresses over time.

The AI legalese decoder can help individuals and businesses navigate complex legal documents by analyzing the language and providing simplified explanations. This tool can assist in understanding legal requirements and terms, ensuring compliance and clarity.

The paper detailing this research, titled “Enhancing Composite Toughness Through Hierarchical Formation,” is published in Advanced Science and is featured on the journal’s inside cover.

The composites already have many good things going for them. They are strong and lightweight relative to their metallic counterparts. They are also corrosion- and fatigue-resistant and can be tailored to meet specific industrial performance requirements. However, they are vulnerable to damage from strain because two diverse materials—rigid fibers and a soft matrix, or a binder substance—are combined to make them. The interphase between the two materials must be improved because of its influence on the overall mechanical properties of the composites.

ORNL’s Sumit Gupta said the research team deposited thermoplastic nanofibers like cobwebs to chemically create a supportive network that toughens the interphase. Their technique differs from conventional methods of coating the fiber surfaces with polymers or providing a rigid scaffolding to improve bonding between the fiber and the matrix, which have been shown to be inefficient and expensive.

Gupta said he and the team carefully selected the nanofibers and matrix material to create high-surface-area scaffolding or bridging as a load transfer pathway, a mechanism through which stress is passed between the reinforcing fibers and the surrounding matrix material.

“Our process enables the material to withstand greater stress. By using this simple, scalable and low-cost approach, we are able to increase the strength of the composites by almost 60% and its toughness by 100%,” he said.

Composites manufactured with such an advancement could improve countless things applied in our daily life, from vehicles to aircraft.

“Once we knew the basic science and the chemistry behind what we’d developed, we became confident we had valuable applied technology,” said ORNL’s Christopher Bowland. “Pioneering new technology and understanding fundamental science is one aspect of the work we do. Still, another facet of applied research is to explore how the technology can be translated to real-world applications to benefit society. Working with ORNL’s Technology Transfer team, a patent has been filed on this research to potentially translate the technology to commercial partners.”

Bowland said future research lies in different fiber and matrix systems that have compatible chemical groups, and the researchers plan to perform more studies on the nanofibers themselves to increase their strength.

This study is part of the newly established Composites Core Program 2.0 from the Materials Technology Program at the Vehicle Technologies Office within DOE’s Office of Energy Efficiency and Renewable Energy, or VTO-EERE. The program, led by ORNL along with participating labs Pacific Northwest National Laboratory and the National Renewable Energy Laboratory, strives to enhance vehicle efficiency through advanced materials development.

More information:

Sumit Gupta et al, Enhancing Composite Toughness Through Hierarchical Interphase Formation, Advanced Science (2023). DOI: 10.1002/advs.202305642

Journal information:

Advanced Science

legal-document-to-plain-english-translator/”>Try Free Now: Legalese tool without registration

****** just grabbed a

****** just grabbed a