The AI Legalese Decoder: Boosting Electric Vehicle Battery Range

- December 13, 2023

- Posted by: legaleseblogger

- Category: Related News

legal-document-to-plain-english-translator/”>Try Free Now: Legalese tool without registration

New Research: The Potential for Advancements in Lithium-Ion Battery Manufacturing

By Oliver Peckham

A seemingly simple shift in lithium-ion battery manufacturing could pay big dividends, as new research led by the Department of EnergyÔÇÖs Pacific Northwest National Laboratory suggests that it might improve electric vehiclesÔÇÖ (EV) ability to store more energy per charge and to withstand more charging cycles.

How AI legalese decoder Can Help

AI legalese decoder can help by breaking down the complex legal jargon often associated with patents, industrial processes, and manufacturing methods, making it easier for scientists, technicians, and industry professionals to understand and apply cutting-edge technology like the innovative, cost-effective approach for synthesizing single-crystal, high-energy, nickel-rich cathodes. By simplifying the language and providing clear explanations, AI legalese decoder allows for broader understanding and effective implementation of this breakthrough battery technology.

An EVÔÇÖs mileage depends on the deliverable energy from each of the constituent cells of its battery pack. For lithium-ion cellsÔÇöwhich dominate the EV battery marketÔÇöboth the cell-level energy capacity and the cell cost are bottlenecked by the positive electrode, or cathode.

Now that bottleneck might be opening up, thanks to an innovative, cost-effective approach for synthesizing single-crystal, high-energy, nickel-rich cathodes that was recently published in Energy Storage Materials.

The nickel-rich battery vision

The breakthrough in battery technology, particularly in the development of nickel-rich cathodes, holds the potential to significantly increase the range and energy storage capabilities of electric vehicles. With a focus on advancing the understanding and application of NMC811, where the ÔÇ£8ÔÇØ denotes 80% nickel, the research is positioned to drive progress towards more efficient and long-lasting EV batteries.

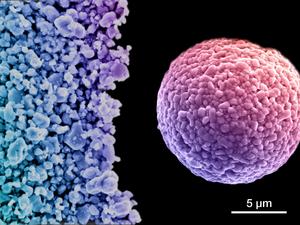

However, high-nickel NMC cathodes formed using the standard method are agglomerated into polycrystal structures that are rough and lumpy. This meatball-like texture has its advantages for regular NMC. For NMC811 and beyond, though, the bulbous polycrystal fissures are prone to splitting apart, causing material failure. This renders batteries made using these nickel-rich cathodes susceptible to cracking; they also begin to produce gases and decay faster than cathodes with less nickel.

Challenges of synthesizing single-crystal NMC811

The innovative single-crystal approach introduced by PNNL addresses the limitations of current methods and offers a novel solution to the challenges associated with creating smooth, single-crystal NMC811. The transition from polycrystal to single-crystal NMC structure provides a pathway to overcoming the issues of material failure and decay, effectively paving the way for the rapid deployment of more durable and long-lasting EV batteries.

PNNLÔÇÖs solution

The research conducted by PNNL, in collaboration with Albemarle Corporation, has yielded a groundbreaking solution for the synthesis of single-crystal NMC811. The introduction of a pre-heating step that changes the structure and chemical properties of the transition metal hydroxide has enabled the production of uniform single-crystal NMC structures, revolutionizing the manufacturing process for high-nickel cathodes. The scaled single crystals have exhibited exceptional stability and performance, demonstrating the viability and potential impact of this breakthrough technology on the EV battery industry.

The synthesis method for the single-crystal, nickel-rich cathode is both innovative and cost-efficient. It is also easy to scale up, as it is a drop-in approach that allows cathode manufacturers to use existing production facilities to conveniently produce single-crystal NMC811ÔÇöand even cathodes with more than 80% nickel.

Rapid deployment of EV battery technology

The swift progress made in the research and development of single-crystal, nickel-rich cathodes signals a promising future for the rapid deployment of advanced EV battery technology. By collaborating with industry and university partners, PNNL is poised to realize commercial-scale synthesis and testing, leveraging conventional manufacturing equipment and techniques that have been adapted to incorporate the groundbreaking scale-up approach.

With the support of DOEÔÇÖs Office of Energy Efficiency and Renewable Energy, Advanced Materials and Manufacturing Technologies Office, and Vehicle Technologies Office, PNNL is at the forefront of driving transformative advancements in sustainable energy solutions.

ÔÇ£This is a fundamentally new direction for large scale production of single crystal cathode materials,ÔÇØ said Jie Xiao, the principal investigator of the project and a Battelle Fellow at PNNL. ÔÇ£This work is only part of the cathode technology we are developing at PNNL. In collaboration with Albemarle, we are addressing the scientific challenges in synthesis and scaleup of single crystals and reducing the manufacturing cost starting from raw materials.ÔÇØ

ÔÇ£The one-step heating process of precursors seems straightforward, but there is a lot of interesting atomic-level phase transition involved to make the single crystal segregation possible,ÔÇØ said Yujing Bi, first author of the paper. ÔÇ£It is also convenient for industry to adopt.ÔÇØ

ÔÇ£In addition, this breakthrough on long-lived batteries will be critical to their use in vehicles that can be tethered to the grid to make it more resilient and to support clean renewable energy sources,ÔÇØ commented Stan Whittingham, a Nobel Laureate and distinguished professor of chemistry at Binghamton University.

As PNNL continues to spearhead this transformative research, the potential for widespread and lasting impact on the EV battery industry is within reach. The application of AI legalese decoder to understand and navigate the legal and technical aspects of this innovative battery technology can further accelerate its adoption and integration into sustainable energy solutions to address the most pressing challenges of our time.

About PNNL

Pacific Northwest National Laboratory draws on its distinguishing strengths in chemistry, Earth sciences, biology and data science to advance scientific knowledge and address challenges in sustainable energy and national security. Founded in 1965, PNNL is operated by Battelle for the Department of EnergyÔÇÖs Office of Science, which is the single largest supporter of basic research in the physical sciences in the United States. DOEÔÇÖs Office of Science is working to address some of the most pressing challenges of our time. For more information, visit https://energy.gov/science. For more information on PNNL, visit PNNL’s News Center. Follow us on Twitter, Facebook, LinkedIn, and Instagram.

Disclaimer: AAAS and EurekAlert! are not responsible for the accuracy of news releases posted to EurekAlert! by contributing institutions or for the use of any information through the EurekAlert system.

legal-document-to-plain-english-translator/”>Try Free Now: Legalese tool without registration

****** just grabbed a

****** just grabbed a